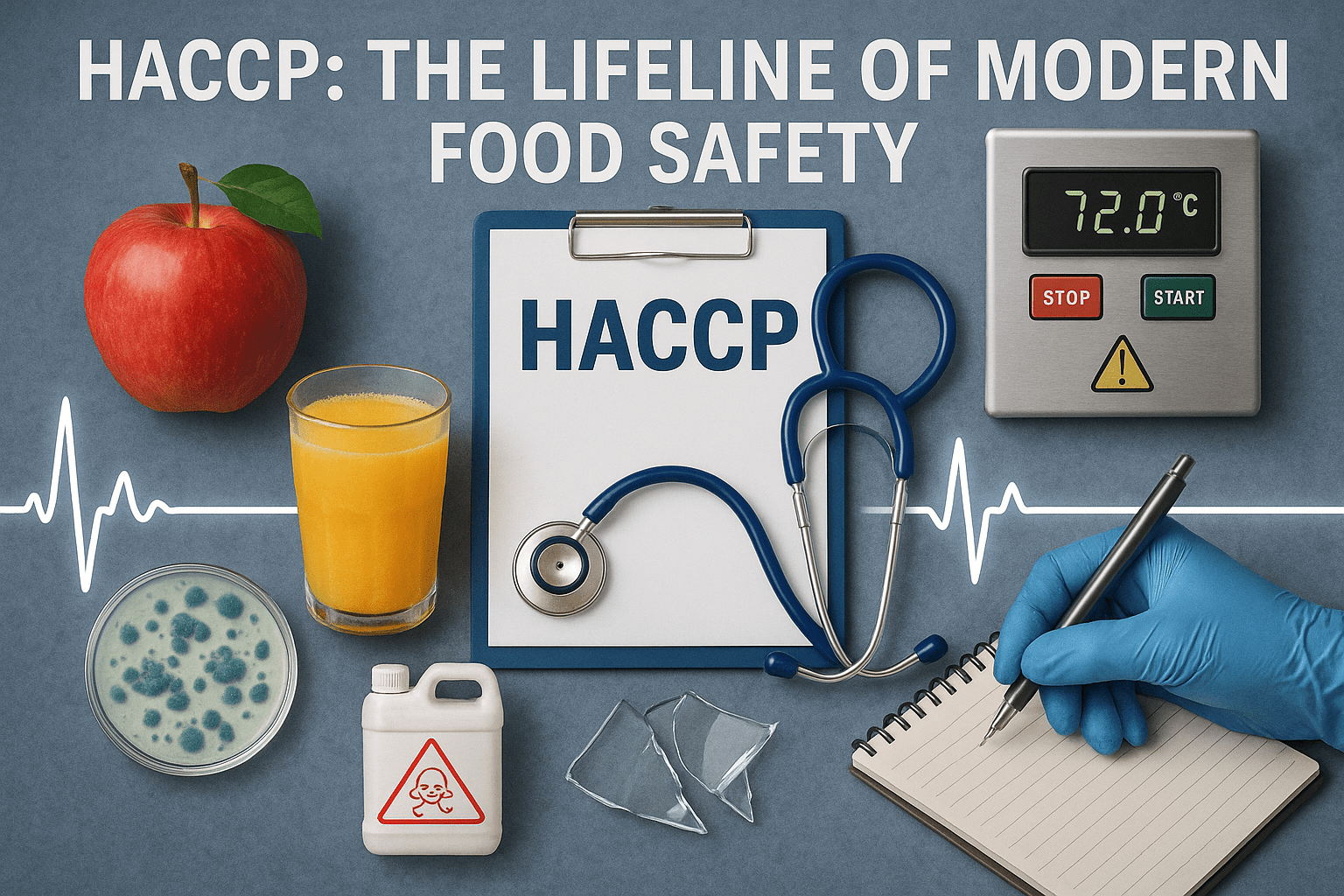

When we bite into a juicy apple, sip on a fresh-pressed juice, or savor a gourmet meal, we trust that the food we eat is safe. But behind that confidence is a powerful, science-based system that has been quietly working for decades to keep our food supply safe—Hazard Analysis and Critical Control Points, better known as HACCP.

What Is HACCP?

HACCP is not a food safety checklist or a one-size-fits-all food safety manual. Instead, it’s a preventive food safety management system that identifies, evaluates, and controls hazards throughout the food production and processing chain. From farm to fork, HACCP is designed to prevent problems before they occur, rather than reacting to food safety failures after they happen.

Originally developed by NASA in the 1960s to ensure safe food for astronauts in space, HACCP has become the global gold standard in food safety. It’s endorsed by the World Health Organization (WHO), the Food and Agriculture Organization (FAO), the U.S. Food and Drug Administration (FDA), the United States Department of Agriculture (USDA)- Food Safety Inspection Service (FSIS), the European Commission, and many other regulatory bodies worldwide.

Understanding Food Safety Hazards

Before diving into how HACCP works, let’s understand what it aims to control – food safety hazards.

These hazards fall into three major categories:

- Biological Hazards

These include bacteria, viruses, parasites, and mold that can contaminate food and cause illness.

- Examples: Salmonella in poultry, Listeria in deli meats, E. coli in raw vegetables.

2. Chemical Hazards

These involve harmful chemical residues, allergens, or toxins that can enter the food supply.

- Examples: Pesticide residues, cleaning agents, undeclared allergens like peanuts or milk.

3. Physical Hazards

These are foreign objects that can cause injury or illness if consumed.

- Examples: Broken glass, metal fragments, plastic pieces from packaging.

Identifying and managing these hazards is the cornerstone of HACCP.

4. Allergenic Hazards

These occur when allergens are unintentionally introduced into food or are not properly declared on labels, posing serious health risks to sensitive individuals.

- Examples: Undeclared peanuts in baked goods, cross-contact with milk or eggs, mislabeled allergen-containing products.

The Seven Principles of HACCP

The HACCP system is built on seven core principles that work together to ensure food safety from start to finish.

- Conduct a Hazard Analysis

This involves identifying all potential biological, chemical, and physical hazards that could affect food safety at each step of production.

Example: In a dairy plant, raw milk might pose a risk of Listeria contamination.

- Determine Critical Control Points (CCPs)

A CCP is a step where control can be applied to prevent, eliminate, or reduce a food safety hazard to an acceptable level.

Example: Pasteurization is a CCP for milk because it eliminates harmful bacteria.

- Establish Critical Limits

For each CCP, a measurable limit is set to distinguish between safe and unsafe conditions.

Example: The critical limit for pasteurizing milk might be heating to 72°C for at least 15 seconds.

- Establish Monitoring Procedures

Monitoring ensures that each CCP stays within its critical limits.

Example: Using temperature sensors to track pasteurization time and temperature.

- Establish Corrective Actions

If monitoring reveals a deviation from critical limits, corrective actions must be taken immediately to protect food safety.

Example: If the pasteurizer fails to reach 72°C, the affected batch is discarded or reprocessed.

- Establish Verification Procedures

Verification ensures the HACCP plan is working effectively, such as reviewing records, calibrating equipment, or conducting microbial testing.

- Establish Record-Keeping and Documentation

Detailed documentation provides traceability and proof of compliance for audits and inspections.

Example: Logs showing pasteurization temperatures, corrective actions, and verification results.

Why HACCP Matters

HACCP isn’t just for food factories or multinational brands—it’s vital for any food business, from small bakeries to global supply chains. When HACCP is well implemented, it:

- Reduces the risk of foodborne illnesses,

- Builds trust with consumers and regulators,

- Meets legal requirements in many countries,

- Prepares businesses for audits and certifications (e.g., ISO 22000, GFSI schemes).

For consumers, the widespread use of HACCP means more confidence that the food on your plate has been produced under strict safety protocols.

Real-World Example: HACCP in Action

Consider a small juice company producing cold-pressed fruit juices. Here’s how HACCP might work:

- Hazard Analysis identifies that raw fruits may carry pathogens.

- A Critical Control Point is established: washing fruits and sanitizing manufacturing equipments before juicing.

- The company sets a critical limit for the sanitizer concentration.

- Monitoring ensures staff test the solution daily.

- If the sanitizer is too weak, a corrective action is taken by adjusting the sanitizer concentration and rewashing the manufacturing equipments.

- Weekly verification involves microbiological testing including that of the final juice.

- All steps are documented to prove due diligence.

This system keeps the product safe and the company compliant with food safety regulations.

Final Thoughts

In a world where food travels thousands of miles and passes through many hands before it reaches your table, HACCP is the invisible guardian that keeps your food safe. It transforms food safety from a reactive process into a proactive strategy—protecting consumers, empowering producers, and enhancing global trade.

Whether you’re a food safety professional, a food entrepreneur, or a curious consumer, understanding HACCP is a big step toward appreciating the complex journey your food takes—and the rigorous science that keeps it safe.