Tools Used in Root Cause Analysis: Failure Mode and Effect Analysis

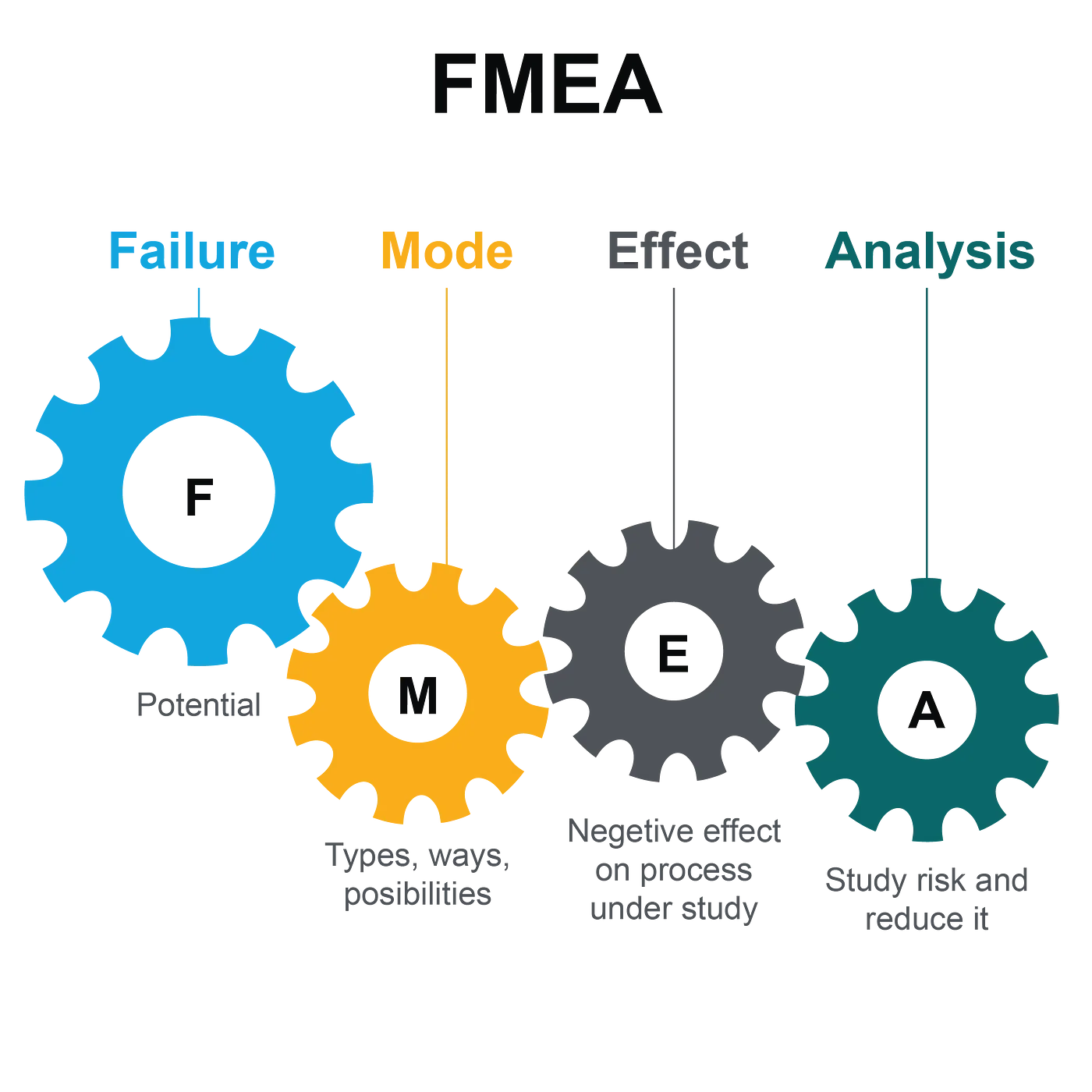

In our previous article leading to this, we discussed using the Fishbone Diagram in root cause analysis and we stated that a fishbone diagram, also known as an Ishikawa diagram, allows you to visually map out potential causes of a problem, categorizing them into different branches such as people, processes, materials, and environment. On the other hand, a Failure Mode and Effect Analysis (FMEA) helps you assess the potential failure modes of a process, product, or system, along with their potential effects. In this episode on “Tools Used in Root Cause Analysis”, we will explore how to use the FMEA to resolve food safety and quality issues in your food business. Prioritizing these failure modes based on severity, occurrence, and detectability can help you focus effort on addressing the most critical issues first.

Failure Mode and Effect Analysis

Unlike most RCA tools that react to existing problems, Failure Mode and Effect Analysis (FMEA) takes a proactive approach, assisting you in identifying potential weaknesses in a system or process before they lead to food safety or quality issues. FMEA functions as a systematic method to assess and mitigate risks.

How to Use the Failure Mode and Effect Analysis

- Define the process/system: To begin the FMEA process, you first define the specific food production or handling step you’re analyzing. This could be a product, service, process step, or entire system within your operation, such as the pasteurization process or packaging line. This clarity ensures a focused analysis of critical points within your operation.

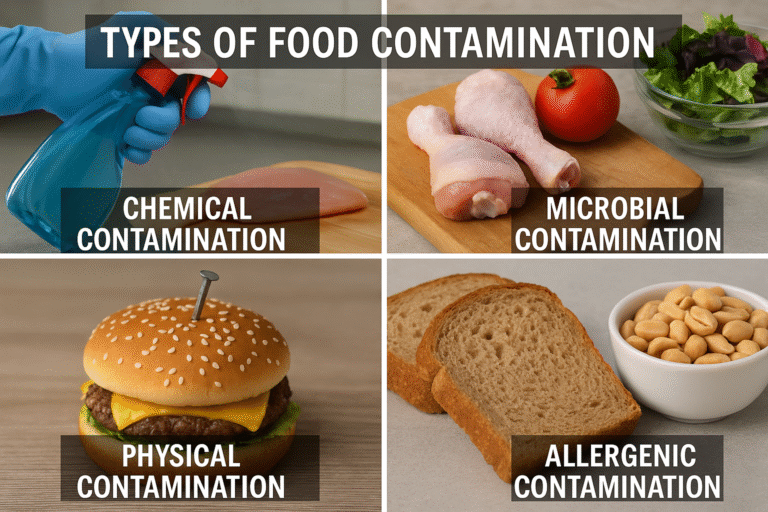

- Identify potential failure mode and evaluate potential effect: Brainstorm by asking what could go wrong. Consider various scenarios, including equipment malfunctions, human errors, and external factors. These could range from improper temperature control during pasteurization to leaking packaging that allows contamination or spoilage. By considering a broad spectrum of potential issues, you can thoroughly evaluate and address vulnerabilities. For each failure mode identified, you assess its potential effects on food safety or quality. This evaluation involves considering the severity of the consequence, such as a food-borne illness outbreak or product recall, along with the likelihood of occurrence, ranging from frequent to rare.

- Identify existing detection control and evaluate detection likelihood: Analyze the existing control measures in place to prevent or detect these failures before they impact the system or process. For example, Safety protocols, quality control checks, and process monitoring systems. Once you are aware of the existing detection control, the next line of action is to evaluate the likelihood of them detecting failure modes before they affect the system.

- Calculate the Risk Priority Number and take action: To prioritize actions, you calculate a Risk Priority Number (RPN) by multiplying the severity, occurrence, and detection likelihood scores for each failure mode. This numerical score helps you pinpoint the most critical areas requiring attention and intervention. Finally, you take action by focusing on addressing the failure modes with the highest RPN scores. This may involve implementing new control measures or improving existing ones to enhance effectiveness and mitigate risks effectively.

For context, let’s say we’re analyzing the pasteurization process for packaged juice.

Failure Mode: Insufficient heating during pasteurization allows harmful bacteria to survive.

Severity: High (Potential food-borne illness outbreak)

Occurrence: Medium (Could happen due to equipment malfunction or human error)

Detection Controls: Temperature monitoring system with alarms.

Detection Likelihood: Medium (Alarms might not be noticed or acted upon promptly)

RPN: Medium (Severity x Occurrence x Detection Likelihood)

Based on the RPN, this failure mode warrants attention. Possible actions could include adding a secondary temperature verification point in the pasteurization line, implementing automated shut-off systems if the temperature falls below a safe threshold, and providing additional training to operators on the importance of monitoring and responding to alarms.

RCA contributes to improved efficiency and cost savings by pinpointing inefficiencies leading to product waste or spoilage, thus optimizing your processes and minimizing waste. It also aids in streamlining your operations by identifying bottlenecks and inefficiencies and enabling smoother workflows.

Do you need assistance with conducting a root cause analysis for food safety and food quality issues in your food business? We are experts in conducting a root cause analysis and we are ready to partner with you to assist your business with resolving food quality and food safety issues so that you can focus on other key areas of running your food business.

FSQ Writer: Oluwatobi Eniyandunmo

Reviewed by: Raphael Samson

Kindly reach out to Fresh Group Food Safety And Quality Consulting for any food quality and safety inquiries.